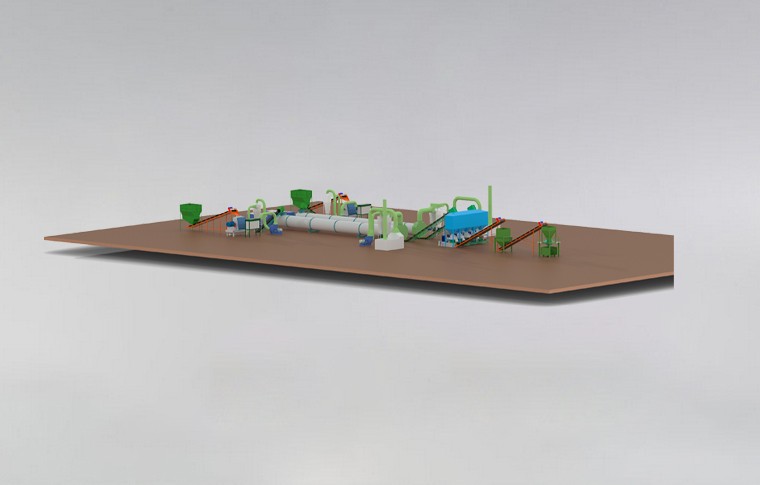

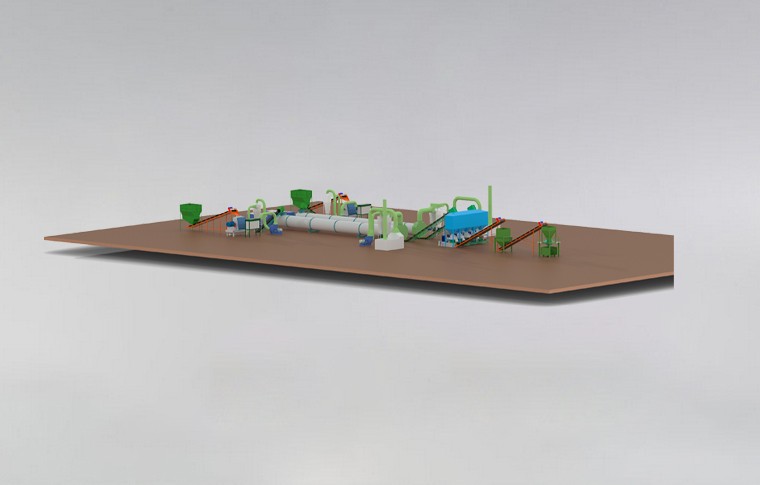

The biomass fuel production line equipment mainly includes wood chipper, hammer mill, dryer, wood pellet mill, cooler, baler and dust removal equipment in each process link.Our high-quality high-tech products not only occupy the Chinese market (including Taiwan, Hong Kong, Macau), but also are exported to the United States, Germany, the United Kingdom, Switzerland, Russia, Morocco, Chile, Brazil, Thailand, Vietnam, Laos, Cambodia, Indonesia, Malaysia Come to more than 20 countries, the company has more than 300 strategic partners around the world.

What equipment and processes are included in the process flow of biomass pellet production line:

1.Wood chipper: The main function is to preliminarily process irregular forestry wastes such as logs and wood scraps into blocks or strips that are conducive to crushing (if the raw materials are like sawdust, you can skip this step).

2. Hammer mill: Wood chips or other small pieces can be further reduced with a pulverizer.

3. Dryer: The material enters the cylinder from the upper part of the drying cylinder through the head of the feed port, the motor drives the drying cylinder to rotate, and the wet material entering the drying cylinder is repeatedly picked up and dropped by the copy board on the wall of the rotating cylinder . With the help of hot air and the rotation of the drying cylinder, it plays the role of drying materials. The dried material is unloaded through the discharge air closer, and the fan is connected to the Shakeron to achieve the effect of dust removal.

4. Wood pellet machine: The raw material falls vertically from the feeding port, and the material is evenly distributed on the surface of the cavity of the mold through the rotation of the pressing wheel. Forms a continuous cylindrical solid body. Easy to transport and burn.

5. Cooler: When the finished pellets leave the pelletizer, they are very hot and will release water vapor. So it must be cooled and dried.

6. Baler: At this step, the pellets are finished and ready to use. But in most cases, storage and transportation are required. Pellets must be stored away from moisture. If the particles absorb moisture, they will expand and become useless. Granules are usually packed in plastic bags and sealed. For most consumers, the bag is an easy-to-carry size. Big bags weighing up to a ton can also be used for larger equipment. Store directly in large silos and ship to consumers in bulk.